Equipment Management Department, Sinopec Yizheng Chemical Fiber Co., Ltd. 211900

Abstract: Daim ntawv no txheeb xyuas qhov txawv txav ntawm qhov loj turbo expander units, tso rau pem hauv ntej ntawm kev ntsuas los daws cov teeb meem, thiab tuav cov ntsiab lus txaus ntshai thiab kev tiv thaiv kev ua haujlwm.Los ntawm kev siv cov kua roj vanish tshem tawm thev naus laus zis, qhov muaj peev xwm zais qhov phom sij raug tshem tawm thiab kev nyab xeeb ntawm lub tsev yog ua kom ntseeg tau.

1. lub ntsiab lus

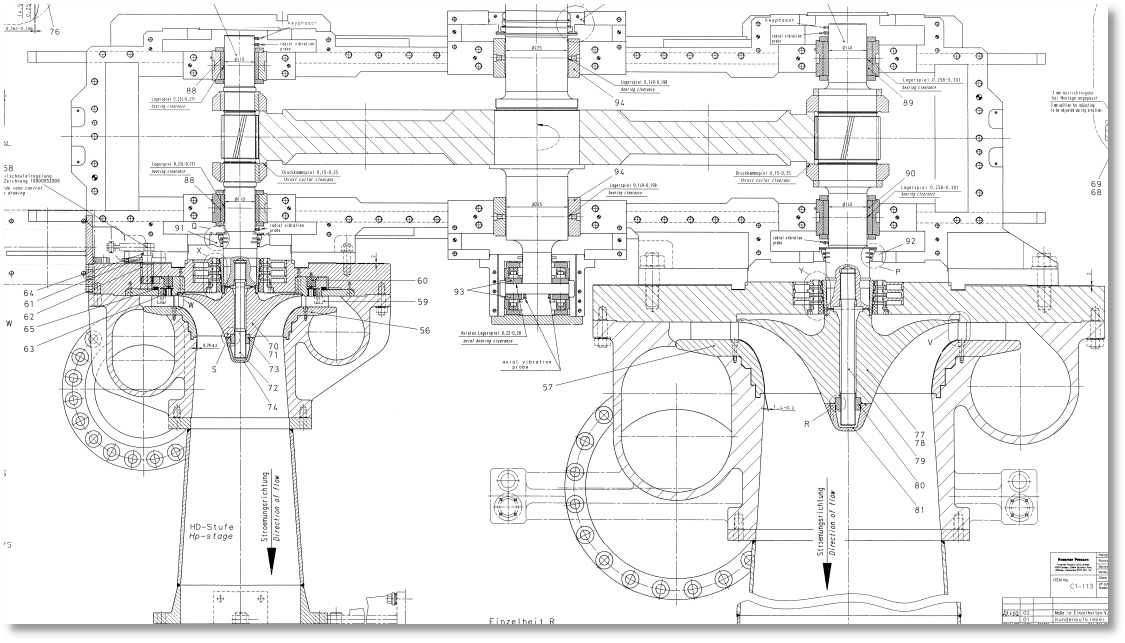

Lub tshuab cua compressor ntawm 60 t / ib PTA cog ntawm Yizheng Chemical Fiber Co., Ltd. yog nruab nrog cov cuab yeej los ntawm lub teb chaws Yelemees MAN Turbo.Chav tsev yog peb-hauv-ib chav, nyob rau hauv uas lub tshuab cua compressor yog ib tug multi-ncej tsib-theem turbine chav tsev, condensing chav turbine yog siv los ua lub ntsiab tsav tsheb ntawm lub tshuab cua compressor, thiab lub turbo expander yog. siv los ua lub tshuab cua compressor.Auxiliary tsav tshuab.Lub turbo expander txais siab thiab qis ob theem nthuav dav, txhua tus muaj qhov chaw nres nkoj nqus thiab qhov chaw nres nkoj, thiab lub impeller txais peb txoj kev impeller (saib daim duab 1)

Daim duab 1 Seem saib ntawm lub expansion unit (sab laug: siab siab sab; sab xis: tsis tshua muaj siab sab)

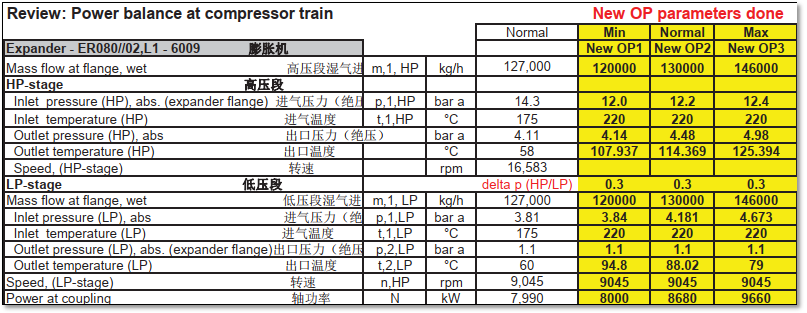

Cov kev ua tau zoo tseem ceeb ntawm turbo expander yog raws li hauv qab no:

Lub siab-siab ceev yog 16583 r / min, thiab qis-siab sab ceev yog 9045 r / min;qhov ntsuas tag nrho lub zog ntawm lub expander yog 7990 KW, thiab tus nqi ntws yog 12700-150450-kg / h;Qhov siab inlet yog 1.3Mpa, thiab lub siab tso tawm yog 0.003Mpa.Qhov ntsuas kub ntawm sab siab siab yog 175 ° C, thiab qhov tso pa tawm yog 80 ° C;Qhov ntsuas kub ntawm qhov qis qis yog 175 ° C, thiab qhov tso pa tawm yog 45 ° C;ib txheej ntawm tilting pads yog siv nyob rau ntawm ob qho kawg ntawm lub siab-siab thiab qis-siab sab iav ncej Bearings, txhua tus muaj 5 pads, cov roj inlet pipeline tuaj yeem nkag mus rau cov roj hauv ob txoj kev, thiab txhua tus kabmob muaj ib qho roj inlet qhov, los ntawm 3 pawg ntawm 15 cov roj txhaj tshuaj nozzles, txoj kab uas hla ntawm cov roj inlet nozzle yog 1.8mm, Muaj 9 cov roj rov qab qhov rau cov kabmob, thiab nyob rau hauv ib txwm muaj, 5 qhov chaw nres nkoj thiab 4 blocks yog siv.Qhov peb-hauv-ib chav tsev no txais yuav txoj kev yuam lubrication ntawm cov roj hauv nruab nrab ntawm cov roj lubricating chaw nres tsheb.

2. Teeb meem nrog cov neeg coob

Hauv xyoo 2018, txhawm rau ua kom tau raws li VOC emission yuav tsum tau, ib chav tsev tshiab VOC tau ntxiv rau cov cuab yeej los kho tus Tsov tus tw roj ntawm cov oxidation reactor, thiab cov roj av kho tau tseem raug txhaj rau hauv lub expander.Vim hais tias cov ntsev bromide nyob rau hauv cov roj av qub yog oxidized ntawm qhov kub thiab txias, muaj bromide ions.Txhawm rau tiv thaiv cov bromide ions los ntawm condensing thiab sib cais tawm thaum tus Tsov tus tw roj nthuav dav thiab ua haujlwm nyob rau hauv lub expander, nws yuav ua rau pitting corrosion rau lub expander thiab cov khoom siv tom ntej.Yog li ntawd, nws yog ib qho tsim nyog yuav tau ua kom lub expansion unit.Qhov ntsuas kub thiab qhov tso pa tawm ntawm sab siab siab thiab qis siab sab (saib Daim duab 1).

Table 1 Daim ntawv teev cov kev khiav hauj lwm kub ntawm lub inlet thiab qhov hluav taws xob ntawm lub expander ua ntej thiab tom qab VOC transformation

| TSIS MUAJ. | Kev hloov pauv | Kev hloov pauv ntawm tus qub | Tom qab kev hloov pauv |

| 1 | Kev kub siab sab sab txais cua kub | 175 ° C | 190 ° C |

| 2 | Siab siab sab tso cua kub | 80 ℃ | 85 ° C |

| 3 | Tsawg siab sab txais cua kub | 175 ° C | 195 ° C |

| 4 | Tsis tshua muaj siab sab tso cua sov | 45 ° C | 65 ° C |

Ua ntej qhov kev hloov VOC, qhov kub ntawm qhov tsis yog impeller sab bearings ntawm qhov qis siab kawg tau ruaj khov ntawm li 80 ° C (lub tswb ntsuas kub ntawm cov kabmob ntawm no yog 110 ° C, thiab qhov kub siab yog 120 ° C).Tom qab qhov kev hloov pauv VOC tau pib thaum Lub Ib Hlis 6, 2019, qhov kub ntawm qhov tsis yog lub impeller sab bearing ntawm qhov tsis tshua muaj siab kawg ntawm qhov nthuav dav tau maj mam nce, thiab qhov kub siab tshaj yog nyob ze rau qhov kub tshaj tshaj plaws ntawm 120 ° C, tab sis Cov kev vibration tsis hloov pauv loj heev thaum lub sijhawm no (saib daim duab 2).

Fig. 2 Daim duab ntawm qhov nthuav dav txaus txaus thiab tsis yog tsav sab ncej kev co thiab kub

1 - khiav kab 2 - tsis yog tsav kawg kab 3 - tsis tsav ncej vibration kab

3. Ua rau kev tsom xam thiab kev kho mob

Tom qab kuaj xyuas thiab tshuaj xyuas qhov ntsuas kub hloov pauv ntawm chav turbine bearings, thiab tshem tawm cov teeb meem ntawm qhov chaw ntsuas ntsuas, cov txheej txheem hloov pauv, kev sib kis zoo li qub ntawm chav turbine txhuam hnav, cov khoom siv nrawm nrawm, thiab qhov zoo, qhov laj thawj tseem ceeb rau kev coj tus kheej kub hloov pauv. yog:

3.1 Yog vim li cas rau qhov kub nce ntawm qhov tsis-impeller sab bearing ntawm qhov qis siab kawg ntawm lub expander

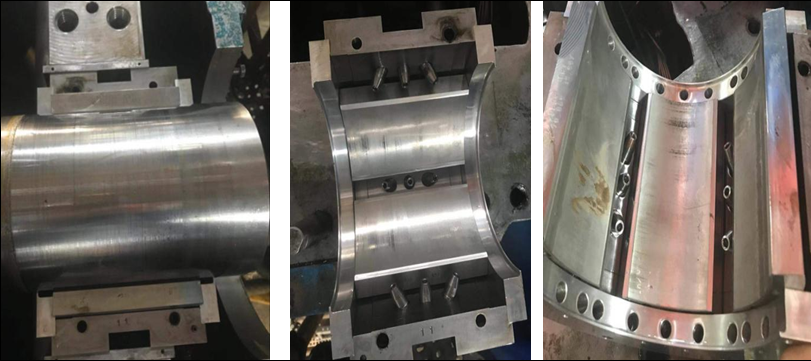

3.1.1 Kev tshuaj xyuas qhov kev tshem tawm tau pom tias qhov kev ncua deb ntawm cov kabmob thiab cov ncej thiab cov meshing clearance ntawm cov hniav iav yog qhov qub.Tsuas yog qhov xav tias cov kua roj vanish ntawm qhov tsis yog impeller sab bearing nto ntawm qhov kawg siab kawg ntawm lub expander (saib daim duab 3), tsis muaj qhov txawv txav nyob rau hauv lwm yam bearings.

Daim duab 3 Lub cev daim duab ntawm qhov tsis-tsav kawg bearing thiab kinematic khub ntawm lub expander

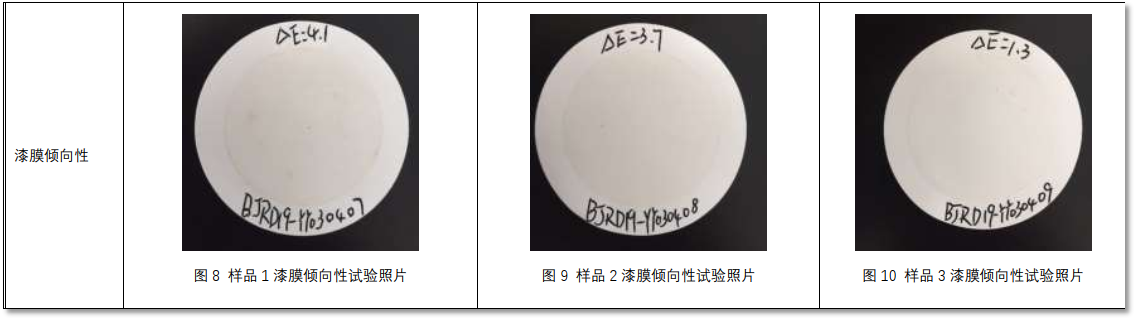

3.1.2 Txij li thaum cov roj lubricating tau hloov qis dua ib xyoos, cov roj zoo tau dhau qhov kev xeem ua ntej tsav tsheb.Txhawm rau tshem tawm qhov tsis ntseeg, lub tuam txhab xa cov roj lubricating mus rau lub tuam txhab kev tshaj lij rau kev kuaj thiab tshuaj xyuas.Lub tuam txhab kev tshaj lij tau lees paub tias qhov txuas ntawm cov kabmob yog cov kua roj vanish thaum ntxov, MPC (cov kua roj vanish propensity index) (saib daim duab 4)

Daim duab 4 Kev soj ntsuam xyuas cov cuab yeej siv hluav taws xob qhia tawm los ntawm cov roj saib xyuas kev tshaj lij thev naus laus zis

3.1.3 Lub lubricating roj siv nyob rau hauv lub expander yog Plhaub Turbo No. 46 turbine roj (mineral roj).Thaum cov roj ntxhia nyob rau hauv qhov kub thiab txias, cov roj lubricating yog oxidized, thiab cov khoom oxidation sib sau ua ke ntawm cov kabmob hav txwv yeem los ua cov kua roj vanish.Mineral lubricating roj feem ntau yog tsim los ntawm hydrocarbon cov khoom, uas yog qhov ruaj khov ntawm chav tsev kub thiab tsis kub.Txawm li cas los xij, yog tias qee qhov (txawm tias tsawg heev) ntawm hydrocarbon molecules raug oxidation cov tshuaj tiv thaiv ntawm qhov kub thiab txias, lwm cov hydrocarbon molecules tseem yuav raug cov tshuaj tiv thaiv kab mob, uas yog tus yam ntxwv ntawm hydrocarbon chain reactions.

3.1.4 Cov kws tshaj lij cov cuab yeej tau tshawb xyuas ib puag ncig ntawm kev txhawb nqa ntawm cov cuab yeej siv lub cev, qhov kev ntxhov siab txias ntawm cov kav dej nkag thiab qhov hluav taws xob, kev kuaj pom cov roj av, thiab kev ncaj ncees ntawm qhov ntsuas kub.Thiab hloov ib txheej ntawm cov kabmob ntawm qhov tsis-tsav kawg ntawm sab qis ntawm qhov nthuav dav, tab sis tom qab tsav tsheb rau ib hlis, qhov kub tseem nce mus txog 110 ℃, thiab tom qab ntawd muaj qhov hloov pauv loj hauv kev vibration thiab kub.Ntau qhov kev hloov kho tau ua kom tau ze rau cov xwm txheej ua ntej ua ntej, tab sis yuav luag tsis muaj txiaj ntsig (saib daim duab 5).

Daim duab 5 Trend chart of related indicators from February 13 to March 29

MAN Turbo chaw tsim tshuaj paus, nyob rau hauv lub tam sim no ua hauj lwm tej yam kev mob ntawm lub expander, yog hais tias lub intake cua ntim yog ruaj khov ntawm 120 t / h, cov zis hwj chim yog 8000kw, uas yog ze rau tus thawj tsim tso zis zog ntawm 7990kw nyob rau hauv ib txwm ua hauj lwm tej yam kev mob;Thaum cov huab cua ntim yog 1 30 t / h, lub zog tso zis yog 8680kw;Yog hais tias qhov nqus cua ntim yog 1 46 t / h, lub zog tso zis yog 9660kw.Txij li thaum txoj haujlwm ua tiav los ntawm sab qis qis nyiaj rau ob feem peb ntawm lub expander, sab qis ntawm lub expander yuav overloaded.Thaum qhov kub siab tshaj 110 ° C, qhov kev vibration nqi hloov pauv loj heev, qhia tias cov kua roj vanish uas tau tsim tshiab rau ntawm qhov chaw ntawm lub tog raj kheej thiab cov kabmob bush raug khawb thaum lub sijhawm no (saib daim duab 6).

Daim duab 6 Lub zog tshuav nyiaj li cas ntawm expansion unit

3.2Mechanism tsom xam ntawm cov teeb meem uas twb muaj lawm

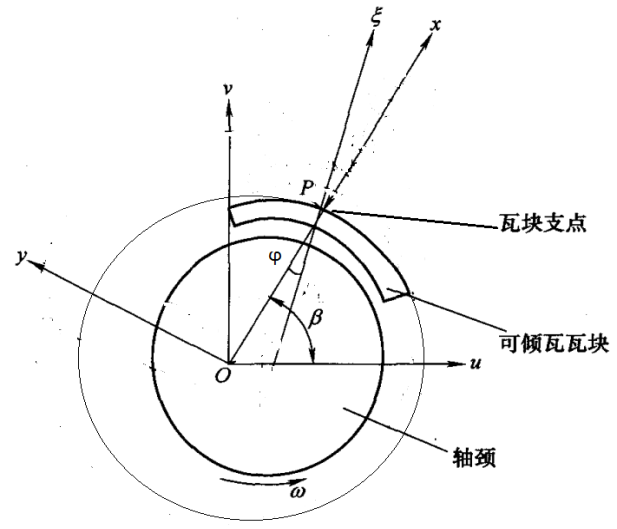

3.2.1 Raws li pom nyob rau hauv daim duab 7, nws yuav pom tau hais tias lub kaum sab xis nyob nruab nrab ntawm lub me ntsis vibration kev taw qhia ntawm lub fulcrum ntawm cov pobzeb thaiv thiab kab rov tav kab nyob rau hauv lub coordinate system yog β, lub viav vias lub kaum sab xis ntawm cov pobzeb thaiv yog φ , thiab tilting ncoo bearing system muaj li ntawm 5 cov vuas, thaum lub pobzeb Thaum lub ncoo raug rau cov roj zaj duab xis siab, txij li thaum lub fulcrum ntawm lub ncoo tsis yog ib tug kiag li nruj lub cev, txoj hauj lwm ntawm lub fulcrum ntawm lub ncoo tom qab compression deformation yuav. tsim ib qho me me txav raws qhov geometric preload kev taw qhia vim qhov nruj ntawm fulcrum, yog li hloov cov kabmob clearance thiab roj zaj duab xis thickness [1] .

Fig.7 Coordinate system ntawm ib lub ncoo ntawm tilting ncoo bearing

3.2.2 Nws tuaj yeem pom los ntawm daim duab 1 tias lub rotor yog cov qauv kab hluav taws xob cantilever, thiab lub impeller yog cov haujlwm tseem ceeb.Txij li thaum lub impeller sab yog tus tsav tsheb, thaum lub roj nthuav dav mus ua haujlwm, lub rotating ncej ntawm lub impeller sab yog nyob rau hauv ib tug zoo tagnrho lub xeev nyob rau hauv lub bearing hav txwv yeem vim cov nyhuv ntawm cov roj damping, thiab cov roj sib txawv tseem zoo li qub.Nyob rau hauv tus txheej txheem ntawm meshing thiab kis torque ntawm lub loj thiab me zog, nrog rau qhov no raws li lub fulcrum, lub radial dawb txav ntawm cov tsis-impeller sab ncej yuav raug txwv nyob rau hauv overloading tej yam kev mob, thiab nws lubricating zaj duab xis siab yog siab dua li ntawm lwm yam. bearings, ua rau qhov chaw no lubricated Cov zaj duab xis txhav nce, cov roj zaj duab xis rov ua dua tus nqi txo, thiab kev sib txhuam kub nce, uas ua rau cov kua roj vanish.

3.2.3 Cov kua roj vanish nyob rau hauv cov roj yog tsim nyob rau hauv peb hom: roj oxidation, roj "micro-combustion", thiab lub zos high-temperature paug.Cov kua roj vanish yuav tsum tshwm sim los ntawm "micro-combustion" ntawm cov roj.Cov txheej txheem yog raws li nram no: ib tug tej yam huab cua (feem ntau tsawg tshaj li 8%) yuav yaj nyob rau hauv lub lubricating roj.Thaum lub sij hawm solubility ntau tshaj, cov huab cua nkag mus rau hauv cov roj yuav muaj nyob rau hauv cov roj nyob rau hauv daim ntawv ntawm suspended npuas.Tom qab nkag mus rau hauv cov kabmob, qhov kub siab ua rau cov npuas no tau nrawm nrawm nrawm, thiab cov kua dej kub nce siab sai ua rau adiabatic "micro-combustion" ntawm cov roj, uas ua rau muaj qhov me me me me insolubles.Cov insolubles no yog polar thiab nyiam ua raws li cov hlau nto los ua cov kua roj vanish.Qhov siab dua, qhov qis dua qhov solubility ntawm cov teeb meem insoluble, thiab qhov yooj yim dua nws yog precipitate thiab khom los ua cov kua roj vanish.

3.2.4 Nrog rau kev tsim cov kua roj vanish, lub thickness ntawm cov roj zaj duab xis nyob rau hauv lub xeev tsis pub dawb yog nyob los ntawm cov kua roj vanish, thiab nyob rau tib lub sij hawm lub renewal ceev ntawm cov roj zaj duab xis yog txo, thiab qhov kub thiab txias yog maj mam nce, uas nce. Kev sib txhuam ntawm qhov chaw ntawm cov kabmob bush thiab cov ncej, thiab cov kua roj vanish tso ua rau tsis zoo cua sov dissipation thiab nce roj kub ua rau siab bearing bush kub.Thaum kawg, cov ntawv xov xwm rubs tawm tsam cov kua roj vanish, uas tau tshwm sim hauv kev sib hloov ntawm kev sib tsoo ntawm cov ncej.

3.2.5 Txawm hais tias MPC tus nqi ntawm cov roj expander tsis siab, thaum muaj cov kua roj vanish nyob rau hauv lub lubricating roj system, lub dissolution thiab nag lossis daus ntawm cov kua roj vanish hais nyob rau hauv cov roj yog txwv vim tsis muaj peev xwm ntawm cov roj lubricating kom yaj. cov kua roj vanish hais.Nws yog dynamic tshuav nyiaj li cas.Thaum nws mus txog lub xeev saturated, cov kua roj vanish yuav dai rau ntawm cov kabmob lossis cov kabmob, ua rau qhov kub thiab txias ntawm cov kabmob pad, uas yog qhov tseem ceeb zais qhov phom sij cuam tshuam rau kev nyab xeeb.Tab sis vim nws adheres rau cov bearings ncoo, nws yog ib qho ntawm cov laj thawj rau qhov kub thiab txias ntawm cov bearings ncoo.

4 Kev ntsuas thiab kev tiv thaiv

Tshem tawm cov kua roj vanish ntawm cov kabmob tuaj yeem ua kom ntseeg tau tias cov kabmob ntawm chav tsev khiav ntawm qhov ntsuas kub.Los ntawm kev tshawb fawb thiab kev sib txuas lus nrog ntau lub tuam txhab ntawm cov khoom siv tshem tawm cov kua roj vanish, peb xaiv Kunshan Winsonda, uas muaj cov txiaj ntsig zoo thiab kev ua lag luam lub koob npe nrov, los tsim WVD-II electrostatic adsorption + resin adsorption, uas yog cov khoom siv tshuaj txhuam cov kua roj vanish tshem tawm cov xim.daim nyias nyias.

WVD-II series roj purifiers zoo sib xyaw electrostatic adsorption purification technology thiab ion exchange technology, daws cov kua roj vanish los ntawm resin adsorption, thiab daws cov kua roj vanish los ntawm electrostatic adsorption.Cov cuab yeej no tuaj yeem txo cov ntsiab lus ntawm cov sludge hauv lub sijhawm luv luv, nyob rau lub sijhawm luv ntawm ob peb hnub, cov txheej txheem lubrication qub uas muaj cov sludge / kua roj vanish tuaj yeem rov qab mus rau qhov zoo tshaj plaws kev khiav hauj lwm lub xeev, thiab cov teeb meem ntawm qhov nce qeeb hauv qhov kub ntawm qhov thrust bearing tshwm sim los ntawm cov kua roj vanish tuaj yeem daws tau.Nws tuaj yeem tshem tawm tau zoo thiab tiv thaiv kom tsis txhob soluble thiab tsis soluble roj sludge generated thaum lub sij hawm ib txwm ua haujlwm ntawm chav turbine.

Nws cov ntsiab cai tseem ceeb yog raws li nram no:

4.1 Ion txauv resin tshem tawm cov kua roj vanish yaj

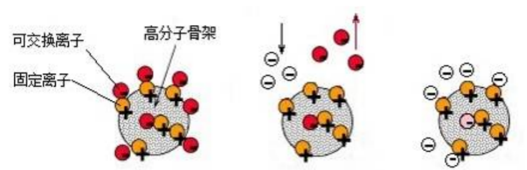

Ion txauv resin feem ntau yog tsim los ntawm ob ntu: polymer skeleton thiab ion pauv pawg.Lub hauv paus ntsiab lus adsorption yog qhia hauv daim duab 8,

Daim duab 8 Lub hauv paus ntsiab lus ntawm ion-interaction resin adsorption

Cov pab pawg sib pauv tau muab faib ua ib feem ruaj thiab ib feem txav tau.Qhov ruaj khov yog khi rau ntawm lub polymer matrix thiab tsis tuaj yeem txav tau yooj yim, thiab dhau los ua ion ruaj khov;qhov txav tau thiab qhov ruaj khov yog ua ke los ntawm ionic bonds los ua ib qho kev sib pauv ion.Cov ions ruaj khov thiab cov ions mobile muaj cov nqi sib txawv.Ntawm cov kabmob hav txwv yeem, lub xov tooj ntawm tes decomposes mus rau hauv kev ywj pheej ions, uas pauv nrog lwm cov khoom degradation nrog tib tus nqi, kom lawv ua ke nrog cov ions ruaj khov thiab ruaj khov adsorbed ntawm lub hauv paus pauv.Nyob rau hauv pab pawg neeg, nws raug tshem tawm los ntawm cov roj, yaj cov kua roj vanish tshem tawm los ntawm ion txauv resin adsorption.

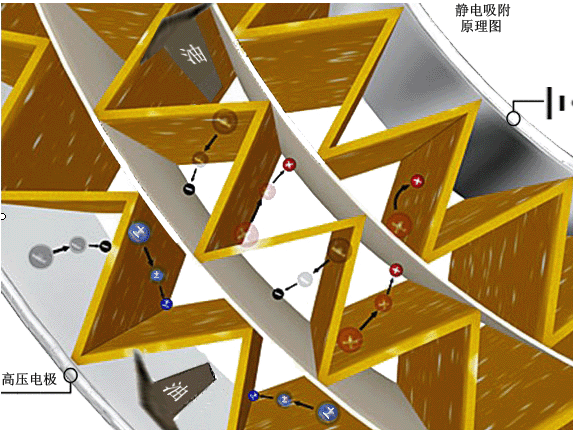

4.2 Electrostatic adsorption technology los tshem tawm cov kua roj vanish

Electrostatic adsorption thev naus laus zis feem ntau yog siv lub tshuab hluav taws xob high-voltage los tsim cov hluav taws xob hluav taws xob hluav taws xob siab kom polarize cov khoom tsis zoo hauv cov roj kom pom cov nqi zoo thiab tsis zoo.Cov khoom nruab nrab yog nyem thiab txav los ntawm cov khoom them, thiab thaum kawg tag nrho cov khoom yog adsorbed thiab txuas mus rau lub collector (saib daim duab 9).

Daim duab 8 Txoj Cai ntawm electrostatic adsorption technology

Electrostatic roj tu tshuab tuaj yeem tshem tawm tag nrho cov kuab paug tsis huv, suav nrog cov khoom tsis huv thiab tshem tawm cov kua roj vanish uas ua los ntawm cov roj degradation.Txawm li cas los xij, ib txwm lim cov ntsiab lus tsuas tuaj yeem tshem tawm cov khoom loj nrog qhov sib xws, thiab nws nyuaj rau tshem tawm cov submicron. qib suspended kua roj vanish.

Cov txheej txheem no tuaj yeem daws cov kua roj vanish precipitated thiab tso rau ntawm cov kabmob ncoo, yog li daws qhov cuam tshuam ntawm cov kabmob pad kub thiab kev vibration hloov los ntawm cov kua roj vanish, kom lub tsev tuaj yeem ua haujlwm ruaj khov rau lub sijhawm ntev.

5 Kev xaus

WSD WVD-II cov kua roj vanish tshem tawm tau muab tso rau hauv kev siv, dhau los ntawm ob xyoos ntawm kev ua haujlwm soj ntsuam, cov kabmob kub ib txwm tau khaws cia nyob ib ncig ntawm 90 ° C, thiab chav tsev tau ua haujlwm zoo li qub.Cov kua roj vanish tau pom (saib daim duab 10).

Daim duab ntawm lub cev ntawm cov kabmob disassembly tom qab txhim kho cov kua roj vanish tshem tawm

khoom siv

cov ntaub ntawv:

[1] Liu Siyong, Xiao Zhonghui, Yan Zhiyong, thiab Chen Zhujie .Cov lej simulation thiab kev sim tshawb fawb txog cov yam ntxwv zoo ntawm pivot elastic thiab damping tilting pad bearings [J].Suav Journal of Mechanical Engineering, Kaum Hli Ntuj 2014, 50(19):88.

Post lub sij hawm: Dec-13-2022